Providing an alternative substitute for the battery

Batteries heavily contribute to the world’s environmental crisis. Only 49% of batteries are recycled in 2020, which causes pollution from unreleased metals.

Full battery degradation can take over 7,000 years and contaminants like mercury affect soil and water for decades. Furthermore, the extraction of rare heavy metals used in batteries, such as nickel, lithium, and mercury, is highly polluting.

7000 years

For a battery to degrade in nature.

Source : Brut Media

Eliminate batteries,

Use light to power

your devices

LAYER® is crafted with Organic Photovoltaic technology. It empowers manufacturers and end users to pioneer a battery-free future by using ambient indoor light to generate sustainable micro-power for devices.

This enhances your product’s intelligence, lifespan, and reduces its environmental impact.

How does it work?

LAYER® revolutionizes the way low-power devices are powered by converting ambient light into electricity.

Ultra thin, flexible and free-shape, LAYER® integrates seamlessly into any product, enabling self-sufficiency and circumventing battery replacement.

LAYER® redefines the playing field

for small electronic devices

Long lifespan

Prolonged lifespan thanks to self-generating electricity.

Adaptable design

Adapts to diverse energy needs and form factors.

Your green energy partner

Your eco-friendly power solution for low-power devices.

Easy integration

Integrates seamlessly.

Optimal Performance in Low Light

Delivers energy even in low light conditions.

Eliminate batteries,

Use light to power your devices

LAYER® is crafted with Organic Photovoltaic technology. It empowers manufacturers and end users to pioneer a battery-free future by using ambient indoor light to generate sustainable micro-power for devices.

This enhances a product’s intelligence, lifespan, and reduces its environmental impact.

How does it work?

LAYER® revolutionizes the way low-power devices are powered by converting ambient light into electricity.

Ultra thin, flexible and free-shape, LAYER® integrates seamlessly into any product, enabling self-sufficiency, eliminating the need for battery replacement.

LAYER® redefines the playing field

for small electronic devices

Long lifespan

Prolonged lifespan thanks to self-generating electricity

Adaptable design

Adapts to diverse energy needs and form factors.

Your green energy partner

Your eco-friendly power solution for low-power devices.

Easy Integration

Integrates seamlessly.

Revolutionary low-light

energy production

Generates energy in low light conditions.

Our technology is used across various industry verticals

Smart Building

Real-time location and status of your assets, such as moving vehicles, packages, and containers.

Asset Tracking

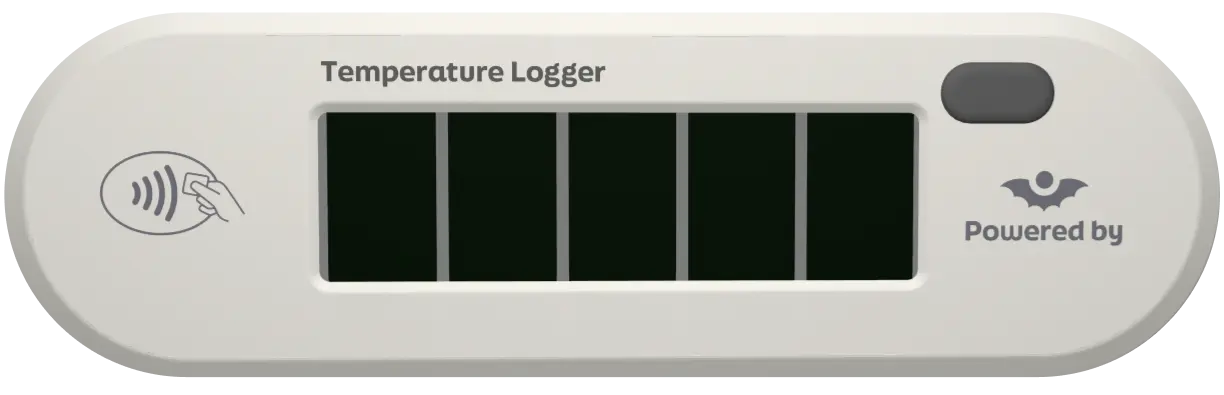

Remote controls, keyboards, thermostats, digital door locks and more.

Smart Home

CO2 sensors, infrared cameras, people counters, temperature or humidity sensors.

Do you have a specific use case in mind you’d like to test?

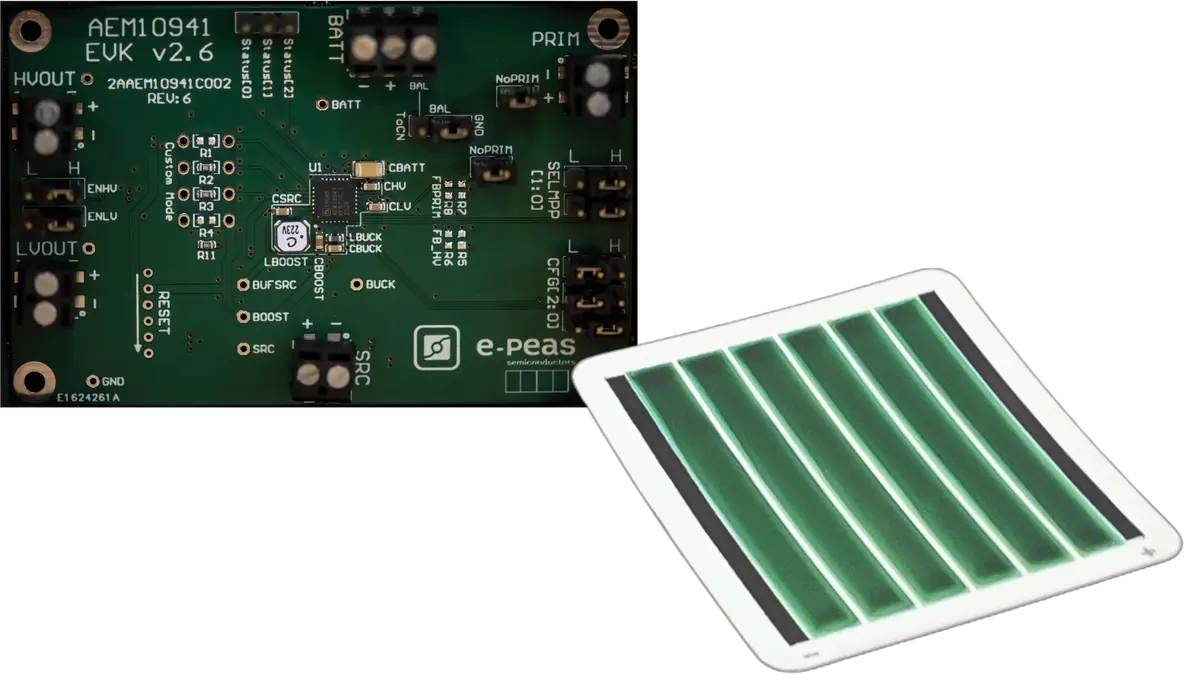

Order a demo kit or an evaluation kit to effortlessly conduct all your tests.

LAYER® Factory

From conceptualization to mass production

In our state-of-the-art Green Micropower Factory, we oversee the large-scale production of premium OPV modules. By leveraging cutting-edge machinery and our team of skilled technicians, we’re committed to meeting high quality and performance standards.

Our ambitious goal is to scale up production to 30 million modules per year by 2024, meeting the expanding customer demand.

Scaling up our production capacity

Embracing a trajectory of expansive growth, we amplify our production capacity to meet surging market demands with unwavering precision and peerless quality, forging prosperous partnerships with our clientele.

Find out more about our production ?

LAYER® Lab

Custom design

& prototyping

We specialize in developing prototypes and pre-series to validate innovative concepts, pushing the limits of energy harvesting technology.

Our team provides a quick and effective transformation of your ideas into functional prototypes. By integrating sustainable energy into your products, we aid in reducing their environmental impact.

LAYER® Factory

From conceptualization to mass production

In our state-of-the-art Green Micropower Factory, we oversee the large-scale production of premium OPV modules. By leveraging cutting-edge machinery and our team of skilled technicians, we’re committed to meeting high quality and performance standards.

We manufacture up to 150 million cm2 of OPV surface yearly, meeting the expanding customer demand.

Scaling up our production capacity

Embracing a trajectory of expansive growth, we amplify our production capacity to meet surging market demands with unwavering precision and peerless quality, forging prosperous partnerships with our clientele.

Find out more about our production?

LAYER® Lab

Custom design

& prototyping

We specialize in developing prototypes and pre-series to validate innovative concepts, pushing the limits of energy harvesting technology.

Our team provides a quick and effective transformation of your ideas into functional prototypes. By integrating sustainable energy into your products, we aid in reducing their environmental impact.

LAYER® Solutions

We build complete products that integrate all components

We build complete products.

We offer comprehensive solutions to manufacturers by providing ready-made products and a variety of licensing options for IoT manufacturers and integrators using our OPV LAYER® technology.

Through our LAYER® Solutions Division we actively support developers designing autonomous applications and help them throughout the implementation, delivery, and support phases of the final product.

Power your future with Dracula Technologies

Cultivating change: Together, for tomorrow

Join our dynamic team and help cultivate change for a better future. At Dracula Technologies, we believe in the power of collaboration to shape a more sustainable, battery-free world. As a member of our team, you’ll be part of a passionate community committed to making a meaningful difference.

Embrace authenticity with us

At Dracula Technologies, every action is guided by integrity. Diversity is celebrated as a strength. Solidarity forges united teams. Fun at work is the driving force behind our culture. These values embody the way we work and grow together.

Looking for more insights?

If you want to explore more news or need detailed information,

please don’t hesitate to check out our news.

- Login

- Sign Up

body::-webkit-scrollbar {

width: 7px;

}

body::-webkit-scrollbar-track {

border-radius: 10px;

background: #f0f0f0;

}

body::-webkit-scrollbar-thumb {

border-radius: 50px;

background: #dfdbdb

}