By Sadok Ben Dhkil, CTO, Dracula Technologies

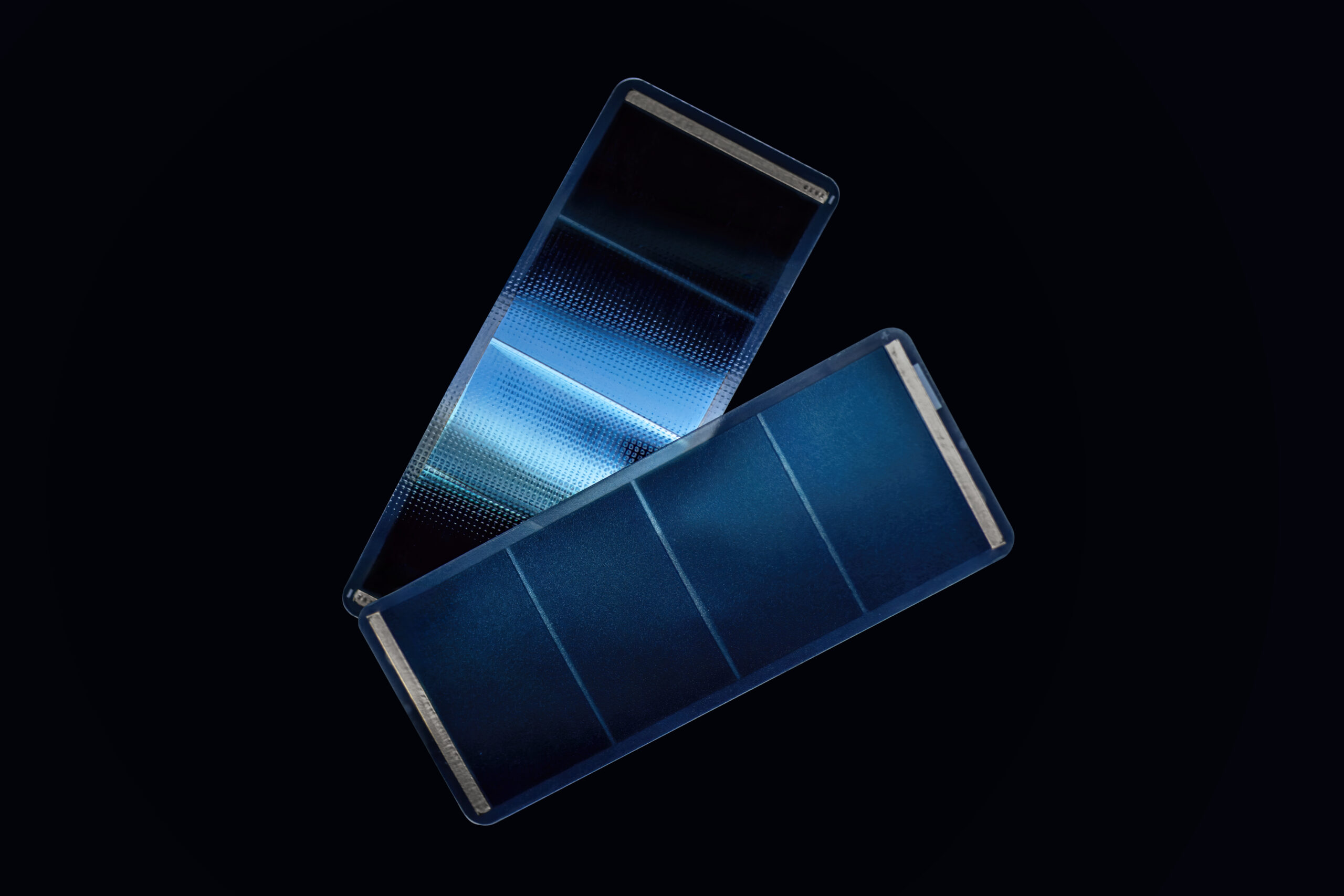

This year at CES 2026, Dracula Technologies showcased its next-generation LAYER® technology for organic photovoltaic (OPV) light energy harvesting modules. The previous generation of OPV represented a significant advancement in the field of renewable energies in terms of flexibility, low production cost, and the diversity of applications it could support compared with more traditional photovoltaic technologies.

This new generation of OPV modules delivers a 30% increase in overall performance with better aesthetics, greater flexibility, adaptable connectivity, and superior sustainability all without comprising durability or reliability.

OPV Architecture

The current nature of the IoT applications like asset tracking, smart building, industry 4.0, and consumer IoT is a heavy reliance on battery-powered sensors. For low-energy sensors, batteries substantially impact maintenance frequency and expense, negatively affecting the overall operating lifetime of the sensor and its Total Cost of Ownership (TCO). Furthermore, companies must grapple with the challenge of meeting ever-evolving regulations for battery-powered sensor use and production. Clearly, there is a compelling need for a more cost-effective and sustainable approach to powering low-energy systems.

An organic photovoltaic (OPV) module is an energy harvesting device that converts ambient light (Natural, artificial, direct, indirect…) into electricity. The technology is so efficient it provides a reliable current and voltage even under limited lighting conditions such as indoor spaces lit primarily by LEDs. OPV energy generation reduces or even eliminates the need for disposable batteries in a wide range of low energy applications, making it an ideal self generating power source for devices like IoT sensors, asset trackers, and remote controls, as well as for a wide range of industrial and consumer smart products.

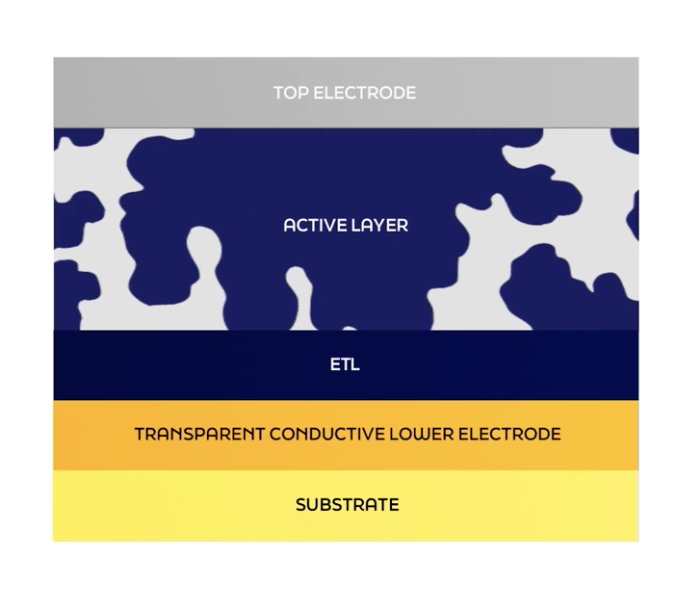

The architecture of an OPV cell focuses on the active area layer where the conversion of photons to electricity takes place. Other layers of a cell, such as the interfacial layers, conductive material, and bus bars or electrodes, are designed to facilitate the extraction and collection of electricalcharges generated in the active area layer. Multiple cells are used together in a single OPV module to generate a higher voltage collectively. Once the OPV layers are printed on the substrate, they must be protected from oxygen and moisture that cause degradation. Currently, a barrier glue is applied over the entire surface, then a barrier film is laminated on top to provide long-term protection and slow module degradation, thus ensuring a service life of at least ten years.

With an OPV module, the active area layer is an organic hydrocarbon layer composed primarily of carbon (C) and hydrogen (H). As the active area absorbs light photons, it generates electron-hole pairs. These pairs are then separated by an internal electric field, producing an electric current that can be extracted outside the module through conductors called busbars.

A layer of conductive material collects the current generated by the active layer. In OPV modules, two layers serve this purpose: the bottom electrode, typically made of indium tin oxide (ITO), and the top electrode. ITO is electrically conductive and, importantly, transparent, allowing light to pass through and reach the active layer for absorption. The top electrode also collects current efficiently, completing the circuit while ensuring minimal interference with light absorption.

The current generated in the OPV module is collected by busbars, which serve both to gather the electrical charges and to connect the module to an external circuit. This arrangement ensures efficient current collection and allows the module to be integrated into different electrical systems.

Enhanced Performance

In the manufacturing process, the OPV active layer is printed on a substrate using an industrial inkjet printer that provides not just a uniform and efficient active area layer, but is also flexible enough to easily support custom cell shapes and configurations at volume scale.

The most important advancement in OPV technology this year is the development of an new active material ink that significantly improves the energy generation capabilities of OPV modules.

This next-generation ink implements two innovations that enhance overall performance:

- Better light absorption: With the new blue active materials, the active area can absorb more light in the visible range. This increases the active area’s overall energy capture capacity, especially under limited indoor lighting conditions where ambient light sources such as LEDs provide reduced light / energy for the cell to harvest.

- Higher conversion efficiency: The next-generation ink used to create the active area of the OPV provides increased electrical performancecompared to the previous generation of ink. This results in an improved open-circuit voltage of between 0.7 and 0.8 volts for each cell.

Together, greater light absorption combined with higher conversion efficiency delivers an impressive 30% overall increase in performance over the previous generation of OPV technology.

Enhanced performance is critical for applications relying on energy harvesting cells translating to direct benefits for OEMs. With 30% enhanced performance, OEMs have greater flexibility and new options:

- Higher power: For a module employing the same OPV cell surface area, OEMs can benefit from 30% higher power without increasing the OPV module footprint.

- Smaller footprint and lower cost: For applications that need the same energy generation capabilities, OEMs can benefit from a module with 30% less active surface area. This results in a smaller module footprint as well as a corresponding reduction in module cost.

- New applications and use cases: OPV energy harvesting technology is now a viable option for many applications that were previously limited by size, capacity, and/or cost considerations.

- Enhanced capabilities: Existing designs can utilize improved OPV modules to support greater functionality than previous generations. For example, a standalone sensor could leverage the 30% enhanced performance to increase its transmission frequency or how much data it collects and sends.

- Increased operating range: Enhanced performance enables devices to operate in lower lighting conditions. Devices that experience dark intervals, such as asset trackers stored in warehouses, can extend how long they can operate.

Better Aesthetics

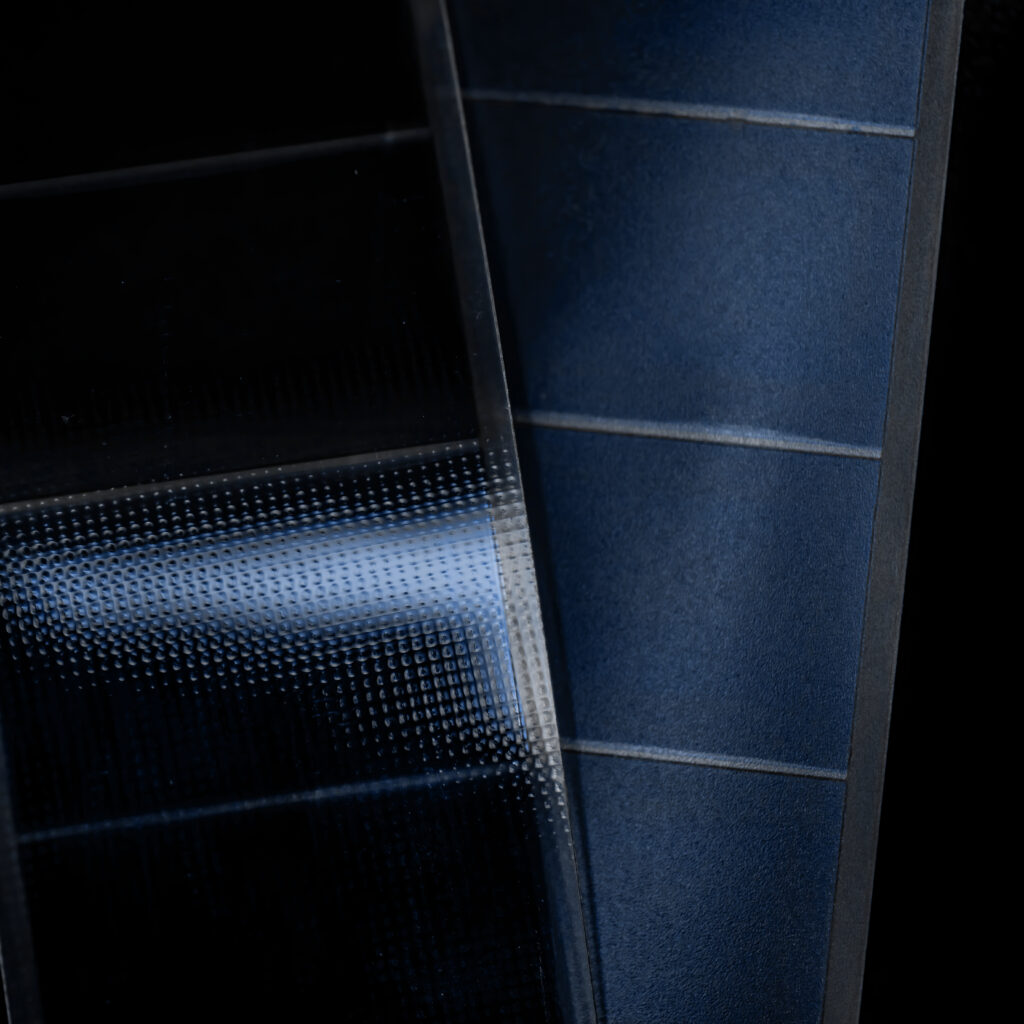

Previous generation OPV modules utilized bus bars made of copper to collect charge generated by the active layer. An important limitation of copper is that it requires a minimum line width of 3 mm. While copper as a material can be laid in a more narrow way, using a line less than 3 mm presents difficulties when fixing it onto the module substrate. This would negatively impact both yield and reliability. Width limitations also determine the area of the dead area that must be left alongside the copper bus bar. This, in turn, reduces the overall potential active area and electrical capacity of the cell.

The next generation of OPV technology has replaced copper bus bars with bus bars made of silver. Since silver is also an excellent conductor, a very fine line can achieve the same performance as a wider copper line. As the bus bar narrows, this shrinks the required dead zone and increases overall power capacity, depending on the layout and dimensions of the active area.

Copper deposition has been replaced with a screen-printing technique using a silver paste. This new approach allows precise control of line width. For example, with a screen-printing mask, it is possible to create lines of silver with a very fine resolution, even as small as 0.5 mm.

As silver generally provides a more uniform visual appearance than copper, silver produces better aesthetics compared to copper. In addition, copperhas a thickness of around 60 micrometres, while the layers composing an OPV module, including the active layer, typically have a thicknesses on the order of 1 micrometre. This wide gap between the two layers is susceptible to visual defects such as trapped air bubbles. Screen printed silver reduces the bus bars to a thickness of 10 to 15 micrometres, thus better bridging the gap between bus bar and active area and leaving less room for defects to form.

Finally, Dracula Technologies has introduced a new decorative coating that will be applied to the module’s top surface to enhance robustness and improve its appearance. This also makes it possible to design more discreet OPV devices and, above all, to provide greater robustness, including improved protection against scratches in applications where the product may be exposed to impacts or mechanical stress. OEMs will be able to choose from different finishes according to their preferences and application needs.

Adaptable Connectivity

To be cost effective, energy harvesting technology needs to not only be efficient but simple to manufacture with. Several years ago, Dracula Technologies introduced Crimp Flex, an efficient connectivity solution for OPV modules that is simple to apply and more adaptable than other technologies.

At a high level, CrimpFlex is a robust interconnection solution that extends metallic wires directly from the OPV module to the internal electrodes. Thanks to their variety of available form factors, these wires can be bent and integrated in a Plug and Play manner with electronic systems. This significantly simplifies the integration of OPV modules and enables scalable, large-scale deployment. In addition, the direct access to electrodes provided by CrimpFlex allows engineers to take energy measurements easily, thus accelerating development by simplifying assessment of OPV modules under different lighting and operating conditions.

Continuing Innovation

As part of its commitment to advancing sustainable energy harvesting technology, Dracula Technologies continues to invest in new innovations to further improve the efficiency, flexibility, aesthetics, and sustainability of its OPV modules. Current research and investment efforts include:

- Organic components: The primary component of an OPV module, the active area layer, is an organic hydrocarbon material. However, other electronic components and materials are necessary for module operation. By continuing to develop organic, eco-friendly alternatives to the non-organic materials used in its modules, Dracula will help OEMs improve the sustainable footprint of their energy harvesting IoT devices and sensors.

- Improved protection: OPV requires a minimum protection level of 10-4 vapor water transmission rate (VWTR) to slow the ingress of humidity

into the module (i.e. only 10⁻⁴ water vapor molecules per square meter per day can pass through the barrier film). The development of stronger barriers will improve resilience and reduce degradation of module efficiency over time, leading to longer module operating lifetimes.

- Thinner films and layers: Reducing the thickness of each layer and the films used results in a thinner module that is lighter and more flexible.

- New form factors: These innovations pave the way for the use of OPV in new applications, notably in the field of smart labels.

With its next-generation LAYER® technology, Dracula Technologies continues to be a leader in light energy harvesting modules. By deliveringgreater efficiency, flexibility, adaptability, and aesthetics, OPV modules bring durable and sustainable energy generation to a whole new range of IoT and smart sensor applications in industrial and consumer applications.